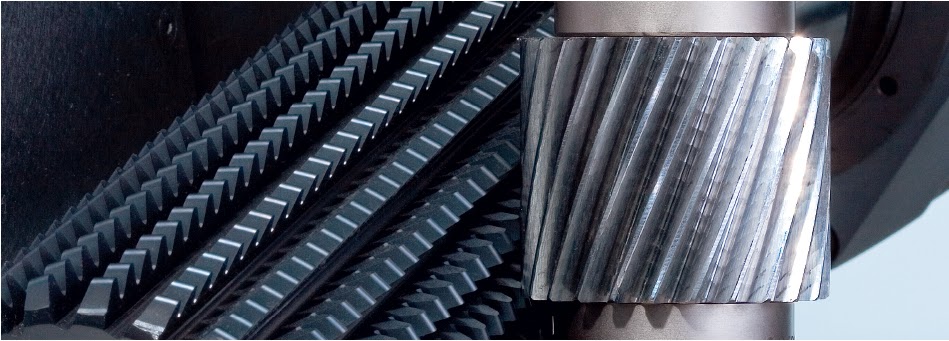

Star SU: System technology from one source

LATEST NEWS

Star SU Announces New Service Manager/Project Coordinator

Farmington Hills, MI, Oct. 11, 2023

Star SU has announced the appointment of Bart Trublowski as its new service manager and project coordinator. Trublowski will oversee service of all the company’s gear manufacturing tools in North America, including its hobbing, chamfer/deburring, and Scudding machines.

LATEST NEWS

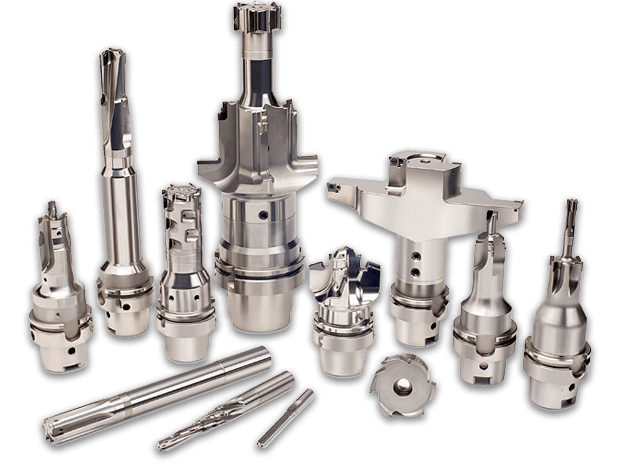

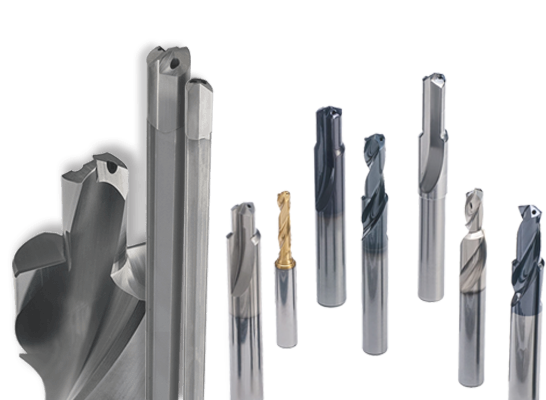

Star SU Named Exclusive Representative for Louis Bélet Products in North America

Farmington Hills, MI, Aug. 2, 2023

Star SU, the marketing, sales and service affiliate of Star Cutter Company, has announced that it has become the exclusive representative of Louis Bélet SA (Switzerland) precision cutting tools in North America.

UPCOMING EVENTS

IMTS 2024

September 9-14, 2024

2024 McCormick Place, Chicago

Chicago, IL

Booth 237013

IMTS 2024 is where the creators, the builders, the sellers, and the drivers of manufacturing technology come to connect, be inspired, and find solutions.