January 16, 2018

In-depth: NTG-6RL Robot Loading System

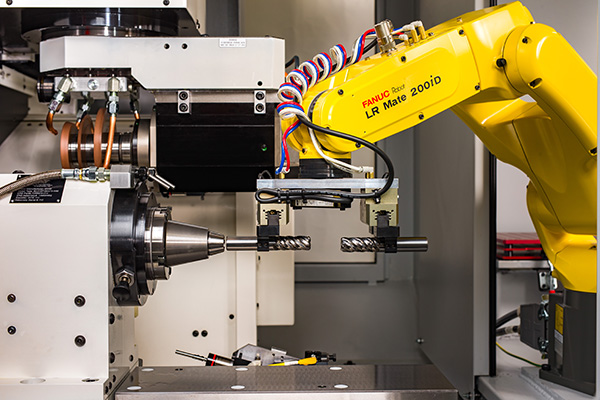

The NTG – 6RL CNC tool and cutter grinder uses a Fanuc 200iD robotic loader with a custom gripper system designed by Star. The robot can change part blanks ranging from 3-32mm in diameter in various workplace lengths, all with the same set of gripper fingers. There is no requirement to change inserts, no re-alignment step, no extended setup times.

Only two data entries are required to use this streamlined loading system. The operator has the ability to tell the robot software interface where on the tool to grip and how many tools to make. The software allows for programming the tool to enter the collet further than the width of the gripper by automatically calculating if a robot double clutch is required and if so, feeds the tool to the desired depth. Additionally, the capability exists to load the tool blank against a hard stop to control overall length by decreasing the system supplied air pressure to the gripper. Part flipping in order to back-work, cutoff, chamfer, or double end the tool completes the list of easily programmed, unique scenarios encountered by many of today’s CNC tool and cutter grinder operators.

On the rare occasion that an operator gets in trouble with the robot, a simple push of the “Robot Home” button will force the robot to retrace its last movements back to the safety of its enclosure. The robot will then replace the tool in the pallet if it still has one in the gripper, saving the operator another step upon restart. The enclosure has an automatic door that separates the robot from the high-pressure coolant spray of the machines work envelope. Since the Fanuc 200iD is not IP67 rated, this harsh environment can contaminate the robots internal mechanisms making separate protection essential to extend years of trouble free operation.

The final benefit to the Fanuc 200iD loading system is the torque sensing option. If it runs into anything for any reason, it will stop before damage occurs. This allows both a fast and durable part loader that even a novice operator can quickly train on and use with confidence.

To learn more about the automatic robot loader on the NTG-6RL click here: http://bit.ly/1ct2scW

Applications Engineering Group – Star Cutter Company